In

the framework of a cooperation project between the university of Freiburg,

institute of image processing and pattern recognition and the company INOS

GmbH, a real-time intelligent robotic system

is being developed, according to which objects of various kinds and shapes,

(mainly card-board boxes and sacks) piled on a platform, should be recognized,

grasped, unloaded and then neatly placed to a target platform. In some cases

the dimensions of the target objects should be calculated a well. We expect to

promote the system to the automobile and cargo distribution industry. Some

examples of the objects which we want to be able to recognize, along with the configurations frequently encountered at

target pallets, are depicted in figure 1.

Figure 1: Target Object

Configurations

In order to

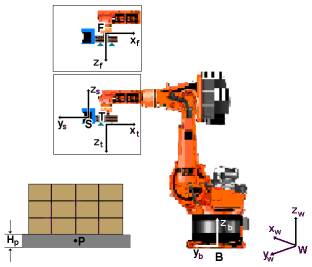

solve this problem, we use an industrial robot from KUKA GmbH, as well as a

SICK LMS200 laser sensor attached on the hand of the robot. Note that the

sensor is placed on the forefront of a gripper, based on vacuum principles. The

robotic system is depicted in figure 4.

Figure 2: The Robotic System

Placing the sensor on the hand of the robot,

has the advantage that scene data can be efficiently acquired. The usage of the

laser sensor as a primary data acquisition tool, renders the system independent

of the environmental conditions. This is very important, since at the future

installation sites, the quality of environmental conditions are adverse.

Cameras will be used in a secondary manner.

According

to the concept described above, we have already implemented an initial system,

which manages to unload card board boxes, which are neatly placed on target

platforms as in figure 4. We have

employed an efficient edge detection algorithm for this purpose, which detects

boxes’ corners from the images of the laser sensor and assumes the boxes position in space. The figure 5a-d

illustrates the system’s operation.

Figure 3: The robotic System in

Action

We want now

to complete the construction of a system which manages to deal with arbitrary

configurations of objects. In this

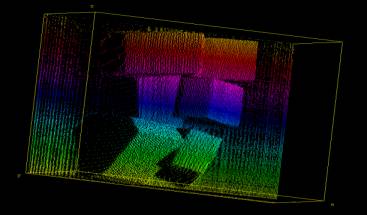

respect, we move the robot’s hand parallel to the objects, having the sensor

pointing to the ground, so as an image of the upper surface of the objects to

be captured. For the configuration of figure 1, the acquired image is depicted

in figure 4.

Figure 4:

Target Object Configuration

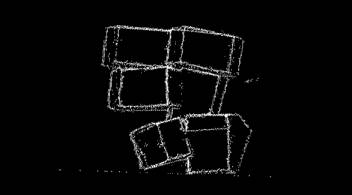

Figure 5: Edge map

Finally,

feature extractors are applied to the image in order to extract characteristics

which will allow for the formation of an hypothesis of the location of the

objects in the scene. For the card - board boxes case, such features could be

the boxes' vertices, which can be relatively easily extracted from the edge map

of figure 5.

We are looking

for two students who will help on the implementation and experimental

evaluation of this robotic system, either as assistants with payment, or

pursuing a diploma thesis. The candidates will have the opportunity to learn

the essentials of developing a state of the art industrial system, as well as

dealing with industrial robots. The candidates should be familiar with basic

knowledge of image processing and capable of programming in C or C++. The

knowledge of written and spoken English is necessary. But what is most

important is imagination and desire for creation! If you feel like having

the above qualifications then email us as soon as possible:

Corresponding person:

Dipl.-Ing. Dimitrios Katsoulas

Albert-Ludwigs-Universität

Freiburg

Lehrstuhl für Mustererkennung

und Bildverarbeitung.

Email: dkats@informatik.uni-freiburg.de

URL: http://lmb.informatik.uni-freiburg.de/people/dkats

Stellenangebote.

Zwei

Stellen für Diplom / Student Arbeiten oder Wissenschaftliche Hilfskräfte, sind ab

sofort zu besetzen. Was wir machen ist ein Kooperationsprojekt zwischen der

Firma INOS Automationssoftware GmbH und

des Lehrstuhles für Mustererkennung und Bildverarbeitung. Ziel des Projektes

ist die Entwicklung eines modularen

Systems mit dreidimensionaler Lage und Positionserkennung von unterschiedlichen, allgemeinen

Objektformen zum intelligenten, roboterunterstützten Depalletieren/Palletieren.

Dass heißt dass wir beim Programmieren eines Industriellen Roboter, einzelne

Objekte wie z.B. Boxen / Kisten, Flachbehälter und Säcke auf einer Palette

lageunabhängig zu erkennen, zu greifen und an anderer Stelle wieder abzulegen

versuchen. Die Ausweitung der zu greifenden Objekte auf Säcke als Vertreter von

Objekten mit variabler Struktur stellt einen zusätzlichen Schwierigkeitsgrad

dar. Mit dem neu zu entwickelnden Erkennungssystem soll es möglich sein, ein

Objekt in Echtzeit zu erkennen und zu greifen. Dieser Vorgang soll von dem

System in einer Zeitspanne bewerkstelligt werden, die auch ein Mensch für die

selbe Tätigkeit benötigt.

Adressaten:

Studenten der Informatik, Physik oder Mathematik mit ausreichenden Kenntnisse in C, C++.

Bei Interesse erhalten Sie

weitere Informationen bei:

Dipl.-Ing. Dimitrios Katsoulas

Albert-Ludwigs-Universität

Freiburg

Lehrstuhl für

Mustererkennung und Bildverarbeitung.

Email: dkats@informatik.uni-freiburg.de

URL: http://lmb.informatik.uni-freiburg.de/people/dkats